Army Supports Summer Interns, Designing New Robots at NJIT Research Center

A little-known R&D facility, operated by NJIT’s New Jersey Innovation Institute with the U.S. Army Picatinny Arsenal for its primary client, is beginning to thrive one year after moving off-campus.

The facility is called COMET — Collaborative Operationalized Manufacturing Engineering and Training — located about 30 miles northwest of NJIT’s Newark campus, close to Picatinny, which is the Army headquarters for conventional weapons development.

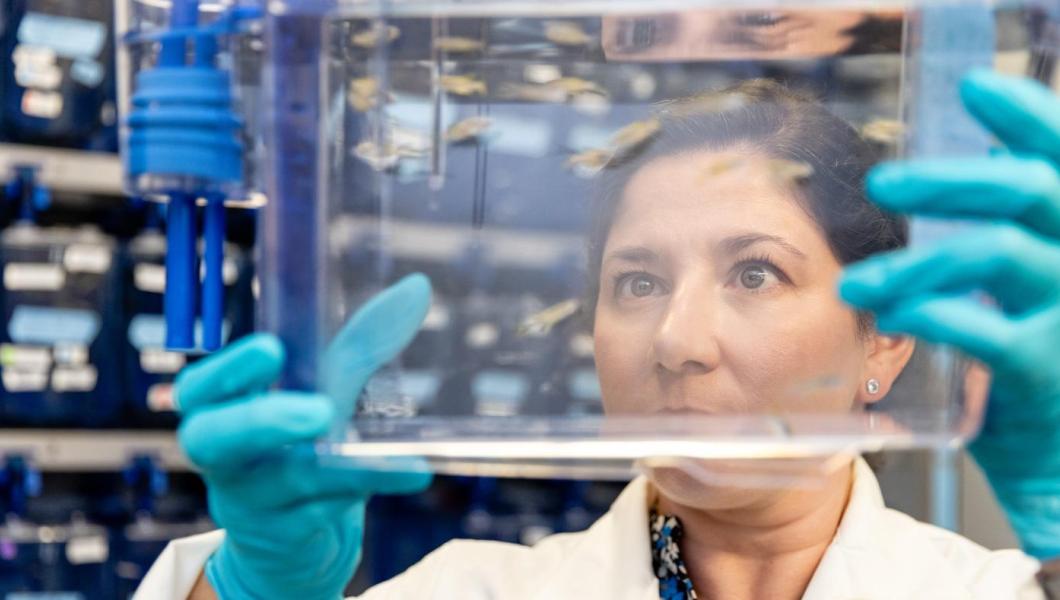

COMET hosts students and faculty throughout the year, not just from NJIT but from various institutions, who all share civic and scientific interest in collaborating with Department of Defense resources but may not want the full commitment of joining the military. Participants must be American citizens. Security clearances aren’t required, but eventually will be for faculty and graduate students in certain projects.

The center is also a place for faculty and graduate students to perform sponsored research, and for industrial manufacturers to display the functions of their latest products.

In the summer, it’s all about undergraduate interns. “We are taking the very talented, technically skilled engineers that are created at NJIT and other universities … and here we throw them into a professional setting,” observed Sam Gatley, director of operations.

About two dozen students participated in a summer 2023 program here, half from NJIT, spanning majors such as computer science, electrical engineering, industrial design, mechanical engineering and physics. Their mission was to design robots that can travel in novel ways through harsh environments, which would serve military, intelligence or civilian applications. Conditions could include ice, mud, snow and water. There could be extreme temperatures, high wind and unexpected terrain.

Robosnakes and hoverdrones

At a group demonstration event, one team showed a snake-like machine that moves by the flow of compressed air serving as its muscles. Another worked on a vehicle that transforms between a hovercraft and drone, while a third built a skiing drone.

On the hovercraft robot, one of the leaders was Sydney Montalto, who is starting her third year as an industrial design major at NJIT’s Hillier College of Architecture & Design. Montalto, from Wood-Ridge, said she applied because she wanted a cool internship. She worked on the hovercraft’s skirt iterations, material selection, shape optimization and arm strength, along with the final presentation.

Montalto said she learned about documentation, group communication, photography, rendering and simulations. Also, she added, “How to work in a team, how to communicate effectively on a large-scale project — I’m getting a lot more technical development skills. Instead of making things more aesthetically pleasing, I’m worrying about the function.”

Origins and return on investment

COMET-twoup.jpg

COMET largely evolved from the AddLab, which enabled 3D printing research through the NJIT physics department. Now that it’s off-campus, the facility has 20,000 square feet of laboratory and office space. Some of its equipment overlaps with the NJIT Makerspace, complementing that facility with a focus on defense applications. It also delves into emerging technology in manufacturing and serves to let defense partner companies highlight the latest systems, such as flexible printed circuits and 3D printing in metal. A clean room is under construction here.

“The return on investment becomes what we do to generate the talent pool and pipeline for Picatinny,” and specifically for the arsenal’s DevCom — officially the Army Combat Capabilities Development Command Armaments Center, said COMET general manager William Marshall. “The void in the talent pool right now is not engineers, it’s technicians. So any of these companies that you talk with about production engineers, they’ll tell you, ’I need people that can get their hands dirty.’”

About 20% of the DevCom Armaments Center's thousands of scientists and engineers hold undergraduate or advanced degrees from NJIT. The alumni include recently appointed director Chris Grassano, an electrical engineer, along with Senior Scientific Technical Manager James Zunino, a chemical engineer who serves as a COMET liaison.

“I’m very happy with the results,” Zunino said. “It’s bringing those different groups and teams together with different skill sets, to see if they can learn from each other. It hasn’t been widely done. It’s a huge value and asset, because it helps find applications and operationalize their learning. It’s almost like finishing school for engineers.”